Carboxymethyl cellulose, hydroxypropyl methyl cellulose, and hydroxyethyl cellulose are used in the largest amounts. Among the three celluloses, the most difficult to distinguish is hydroxypropyl methyl cellulose and hydroxyethyl cellulose. Below, we will distinguish these two celluloses by use and function.

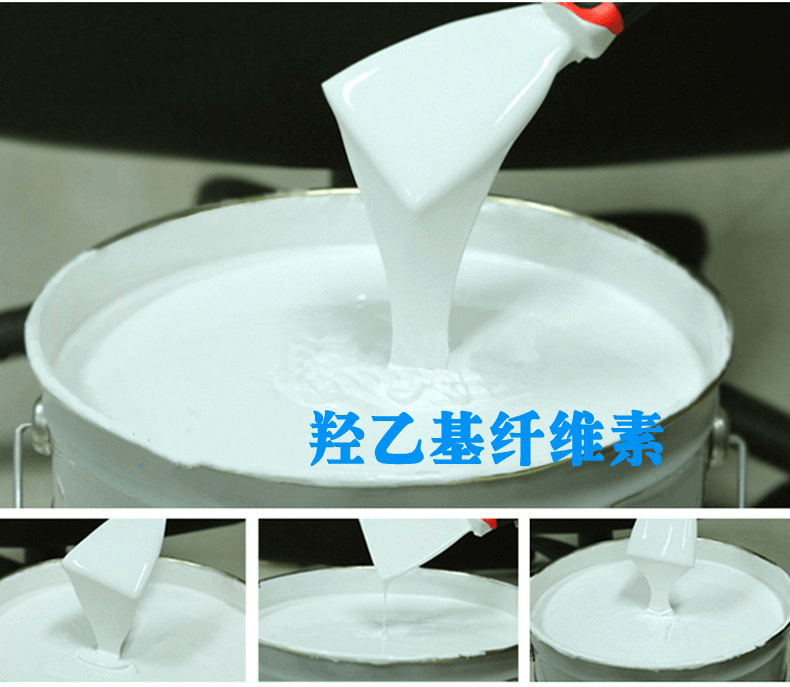

As a non-ionic surfactant, hydroxyethyl cellulose has the following properties in addition to suspending, thickening, dispersing, floating, bonding, film-forming, water-retaining and providing protective colloids, etc:

1. The non-ionic HEC itself can coexist with other water-soluble polymers, surfactants and salts in a wide range. It is an excellent colloidal thickener containing high-concentration electrolyte solutions.

2. Compared with the recognized methylcellulose and hydroxypropyl methylcellulose, the dispersion ability of HEC is the worst, but it has the strongest protective colloid ability.

3. The water retention capacity is twice that of methyl cellulose, and it has better flow regulation.

4. HEC is soluble in hot or cold water, and does not precipitate at high temperature or boiling, making it have a wide range of solubility and viscosity characteristics, and non-thermal gelation.

HEC use: generally used as a thickener, protective agent, adhesive, stabilizer and preparation of emulsions, gels, ointments, lotions, clear eyes.

Application introduction of hydroxypropyl methyl cellulose (HPMC):

1. Paint industry: As a thickener, dispersant and stabilizer in the paint industry, it has good compatibility in water or organic solvents. As a paint remover.

2. Ceramic manufacturing industry: widely used as a binder in the manufacturing of ceramic products.

3. Others: This product is also widely used in leather, paper products, fruit and vegetable preservation and textile industries, etc.

4. Ink printing: As a thickener, dispersant and stabilizer in the ink industry, it has good compatibility in water or organic solvents.

5. Plastics: used as mold release agent, softener, lubricant, etc.

6. Polyvinyl chloride: Used as a dispersant in the production of polyvinyl chloride, and is the main auxiliary agent for the preparation of PVC by suspension polymerization.

7. Construction industry: As a water-retaining agent and retarder for cement mortar slurry, the mortar has pumpability. Used as a binder in plaster, plaster, putty powder or other building materials to improve spreadability and prolong operation time. It can be used as a paste tile, marble, plastic decoration, paste enhancer, and can reduce the amount of cement. The water retention properties of HPMC prevent the slurry from cracking due to drying too fast after application, and enhance the strength after hardening.

Post time: Sep-23-2020