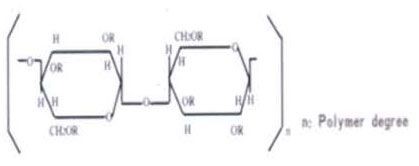

Hydroxyethyl cellulose (HEC)

Structural formula

Technical index

| appearance | White or yellowish powder |

| Molar substitution(MS) | 1.8-2.8 |

| Water insoluble(%) | ≤0.5 |

| Loss on drying(WT%) | ≤5.0 |

| Burning residue(WT%) | ≤5.0 |

| PH | 6.0-8.5 |

| viscosity(mPa.s)2%,20℃ aqueous solution | 30000、50000、100000 |

the physicochemical properties

This product is white or yellowish, odorless, tasteless and easy to flow powder, 40 mesh sieving rate ≥ 99%; softening temperature: 135-140 ℃; apparent density: 0.35-0.61g/ml; decomposition temperature: 205-210 ℃; combustion speed is slow; equilibrium temperature: 23 ℃; 6% at 50% RH and 29% at 84% RH.

It is soluble in cold water, soluble in hot water, but insoluble in most organic solvents. The viscosity changes little in the pH range of 2-12, but the viscosity decreases beyond this range.

Advantages of hydroxyethyl cellulose

As a nonionic surfactant, hydroxyethyl cellulose has the following properties besides thickening, suspension, adhesion, floatation, film-forming, dispersion, water retention and colloidal protection

1. HEO can be dissolved in hot water or cold water, high temperature or boiling without precipitation, so that it has a wide range of solubility and viscosity characteristics, and non thermal gelatinization

2. The non-ionic type can coexist with other water-soluble polymers, surfactants and salts in a wide range. It is an excellent colloidal thickener containing high concentration electrolyte solution

3. The water holding capacity is twice as high as that of methyl cellulose, and it has better flow regulation

4. Compared with methylcellulose and hydroxypropyl methylcellulose, HEC has poor dispersibility, but strong colloidal protection ability.

Solution preparation method

1. Add the specified amount of clean water to the container;

2. Add hydroxyethyl cellulose under low speed stirring until all materials are completely wet;

3. Stir until all the hydroxyethyl cellulose is completely dissolved, and then add other components of the formula to mix well.